HOME > EXPERTISES > INDUSTRIAL VALORISATION OF MICROALGAE > REDUCING CO₂ EMISSIONS

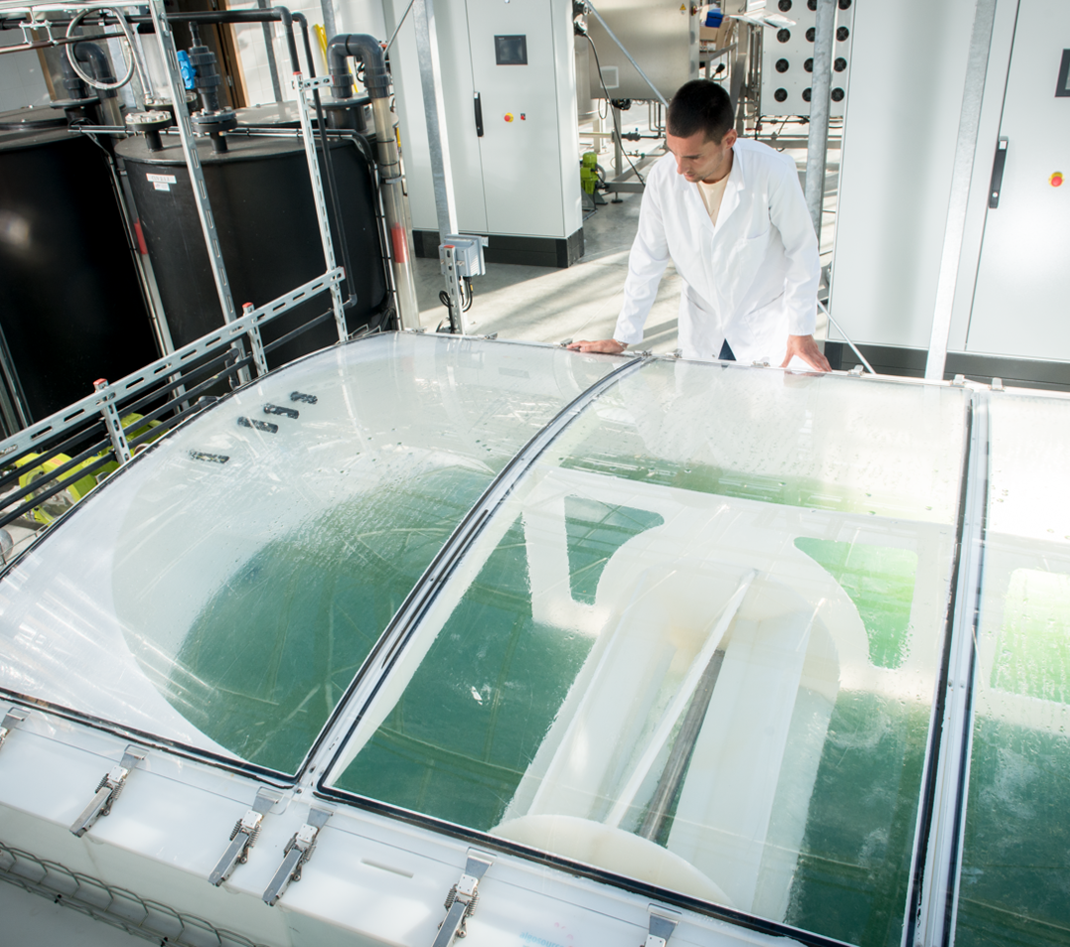

Microalgae cultivation offers a solution for CO₂ capture and is therefore particularly interesting for heavy industries such as cement, steel, chemicals, fertilizers and waste-to-energy.

Proof in numbers

Microalgae use CO₂ as a carbon source in their photosynthesis, contributing to the absorption of CO₂ excess from industrial processes.

Microalgae can be cultivated using this heat excess, optimizing the energy efficiency of facilities.

Microalgae make it possible to reduce the use of conventional materials (such as limestone or clay), which are responsible for large CO₂ emissions during processing.

Microalgae can produce value-added resources (biomass, bioenergy, chemicals), generating new revenue streams.

We bring top-tier expertise in microalgae, offering a wide range of technical and applied skills to drive innovation forward.

State of the art

To identify the best innovation opportunities.

Starting from:

10K€

Duration:

1-3 months

Feasibility study

To integrate microalgae cultivation into an industrial process.

Starting from:

10K€

Duration:

1-3 months

Proof of concept

Validation of the innovation at pilot-scale prior to investment.

Starting from:

30K€

Duration:

6 months

Industrialization

Scaling at pre-industrial level to maximize impact.

Starting from:

50K€

Duration:

8 months

They benefit from turnkey solutions based on well-established expertise.

★★★★★

“We are hosting the demonstrator, essentially large ponds, where spirulina will be cultivated in our main cement plant in Montalieu-Vercieu.”

Renaud C. - Project Manager, VICAT

★★★★★

“Their approach, combining scientific expertise with an understanding of industrial challenges, allowed us to make informed decisions by integrating both technical performance and return on investment.”

Philippe G. - CEO, SARA

★★★★★

“By building on feedback from similar projects that faced significant challenges in terms of profitability and feasibility, the proposed solution stands out as both innovative and promising.”

Toinou F. - R&D project management at GRDF

4 days of theoretical and practical training covering the entire microalgae production chain: from media and inoculum preparation to final biomass harvesting under solar conditions.

A similar project?

We are ready to assist you.

This site uses cookies and gives you control over what you want to enable