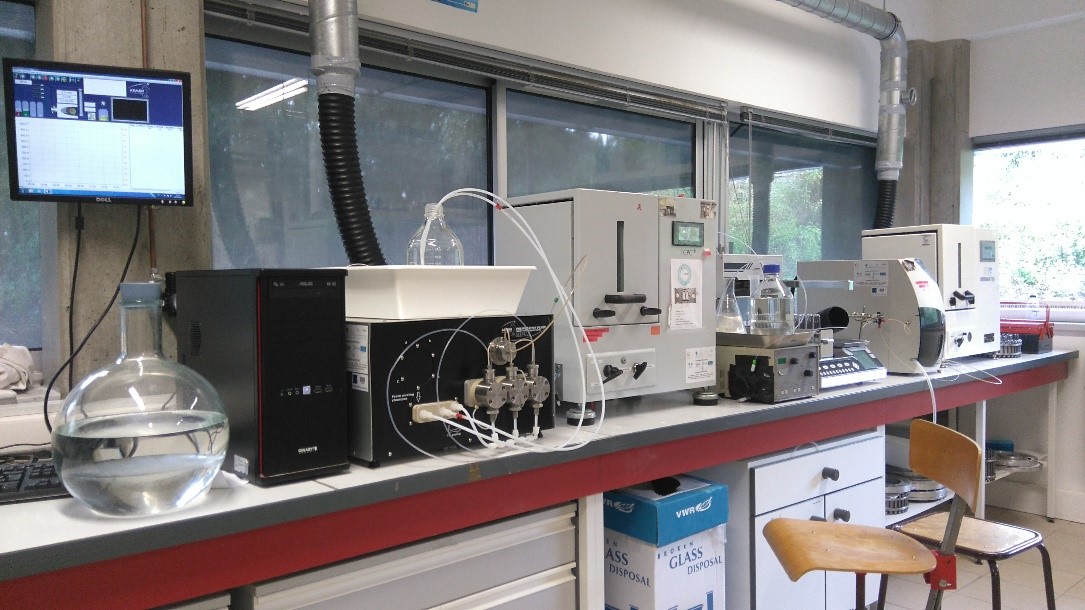

Molecule Extraction and Purification

Comparing extraction processes, purifying natural and synthetic substances, and developing methods for fractionating molecules of interest

- Reactive extraction

- Distillation

- Membrane filtration

- High-performance liquid chromatography (HPLC)

- CCD (Counter Current Distribution)

- Flash chromatography