-

Our Expertise

- See all Our Expertise

- Analytical chemistry

- Biodegradability tests for chemical substances

- Centrifugal Partition Chromatography

- Data science and Artificial Intelligence

- Enzymology and Glycochemistry

- Gene therapy

- Industrial valorisation of microalgae

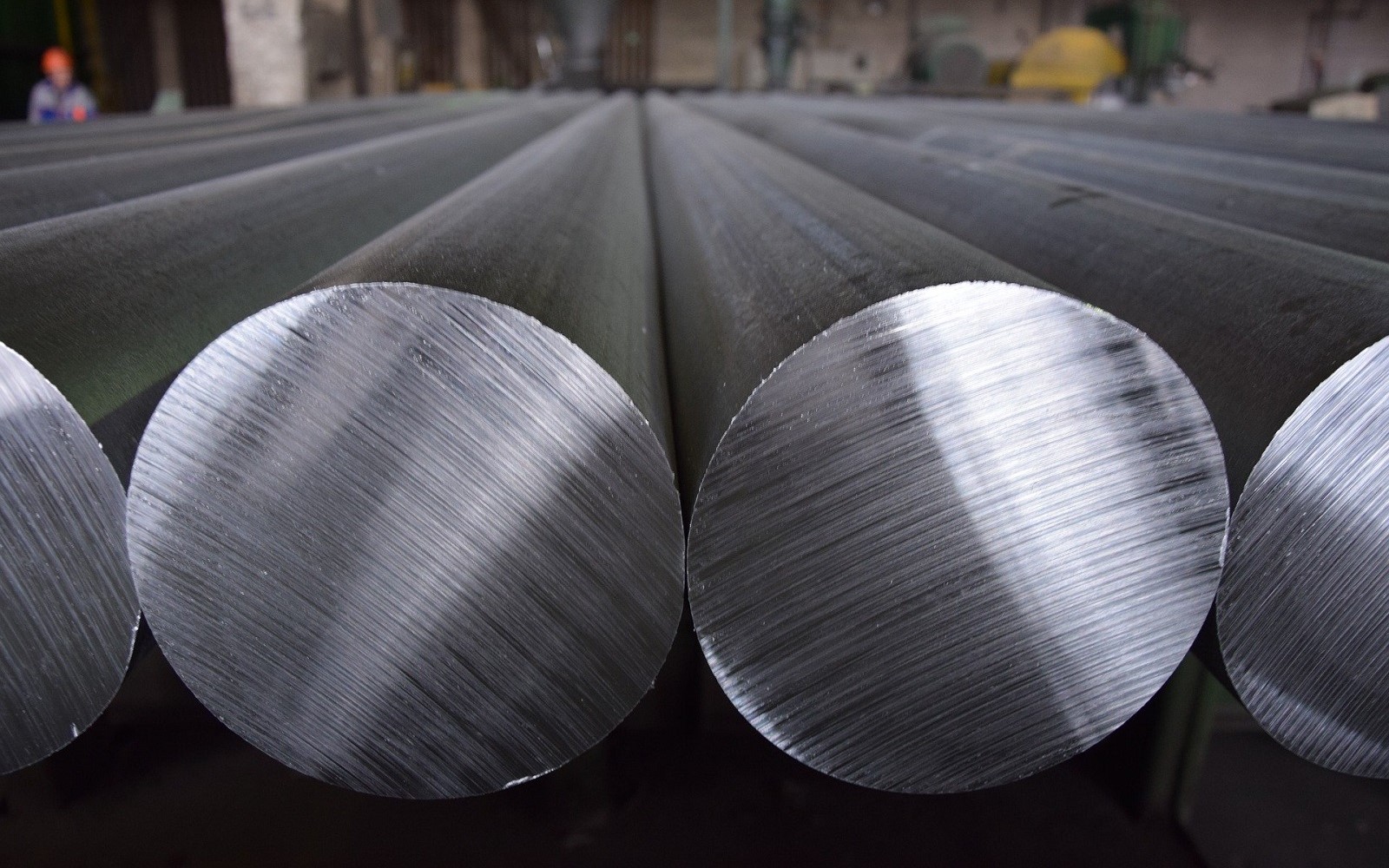

- Materials

- Mechanical

- Preclinical trials

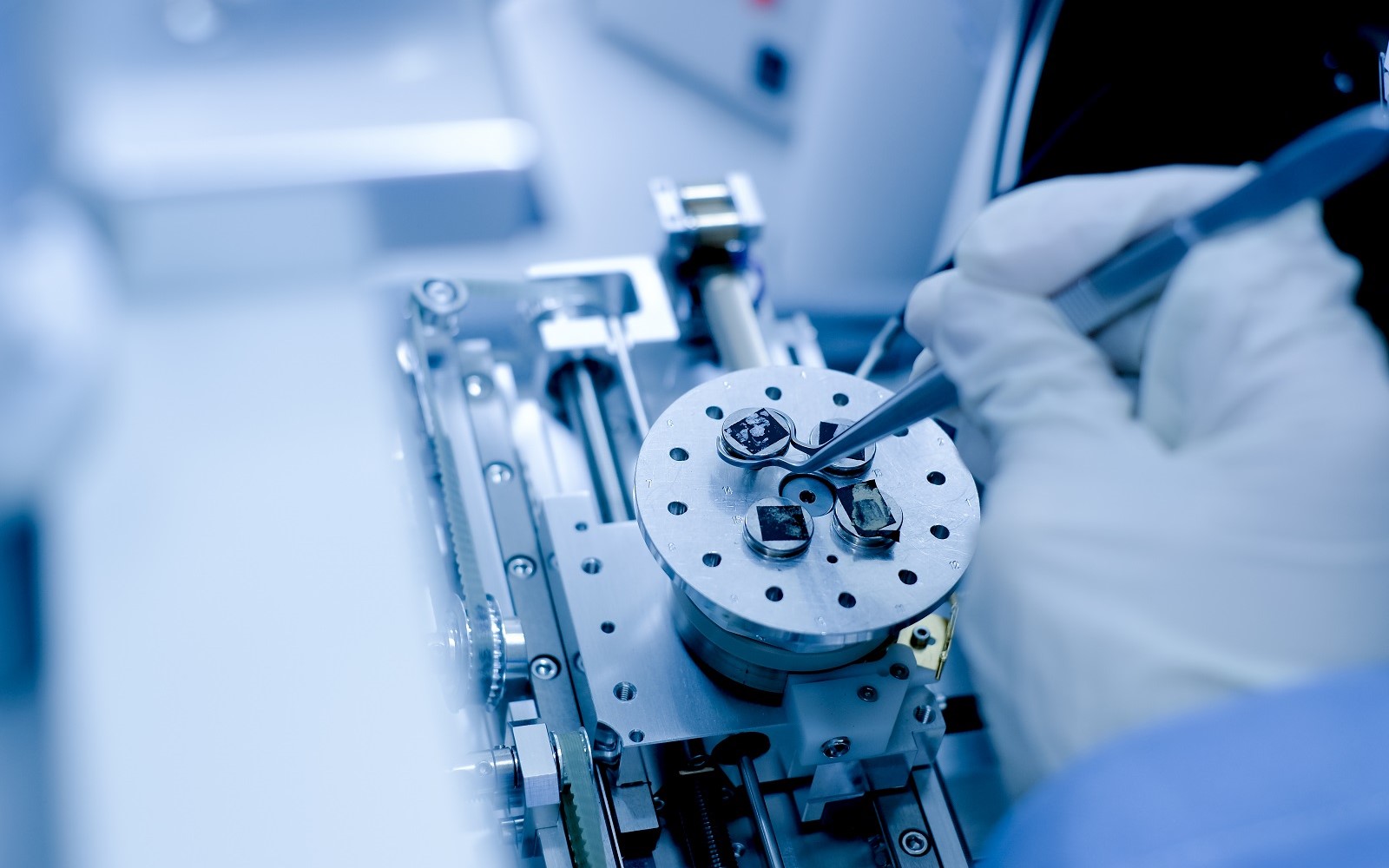

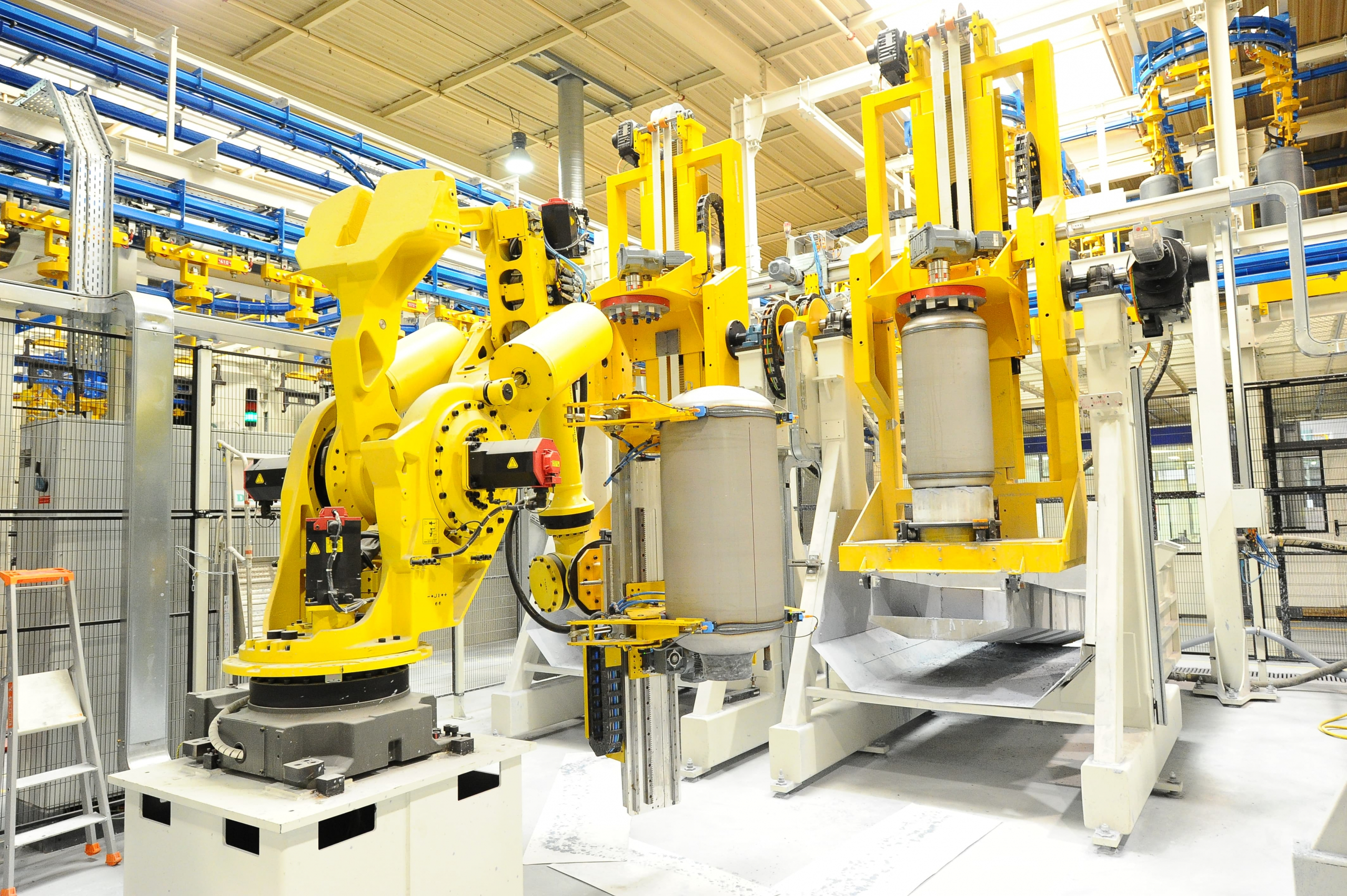

- Robotic and Automation

- Thermal Transfer

-

Follow our adventures

-

#ReadyOrNot

Subscribe

to our Newsletter

-