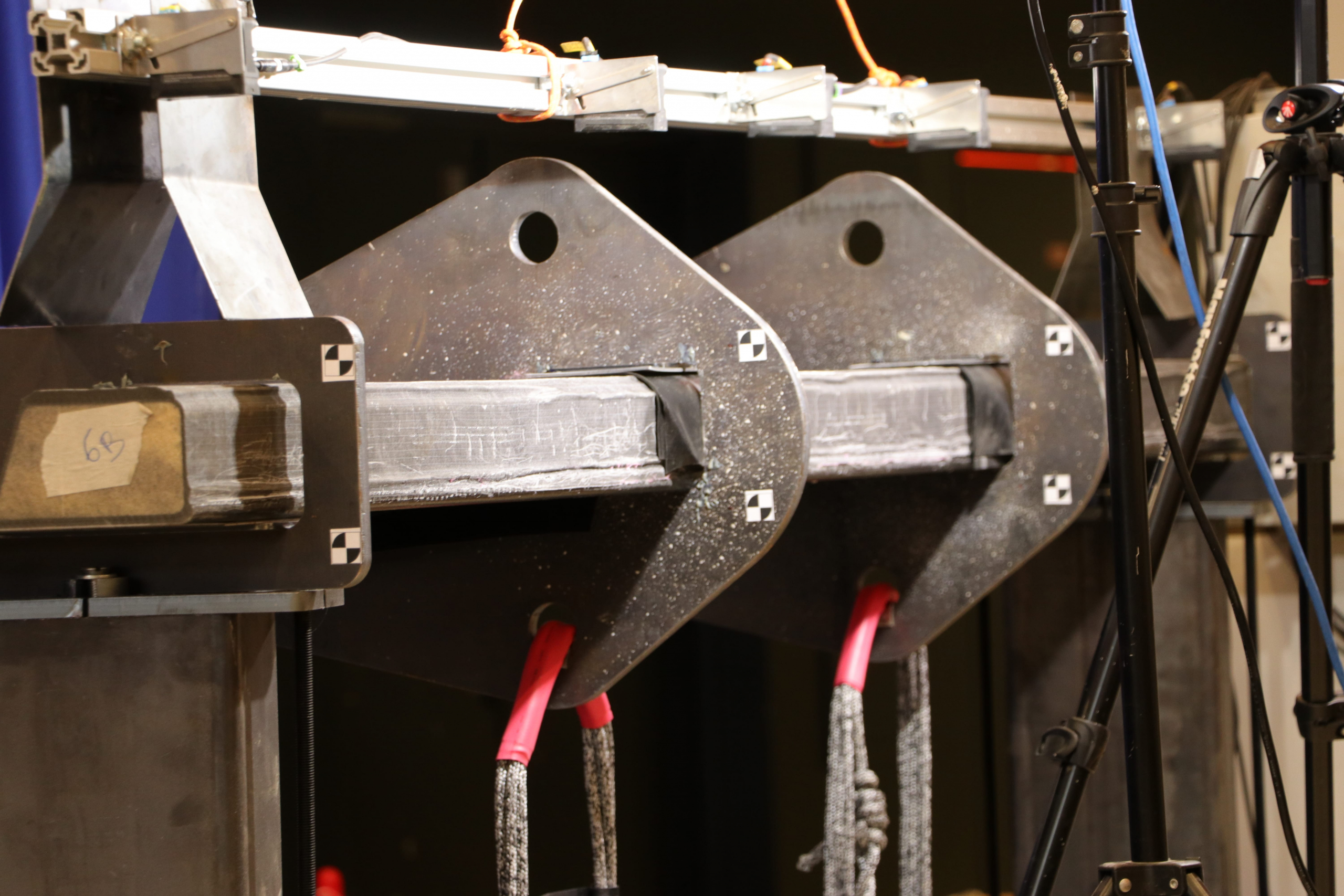

Static strength tests

Entrusting a local laboratory with your standardized static or custom-developed tests.

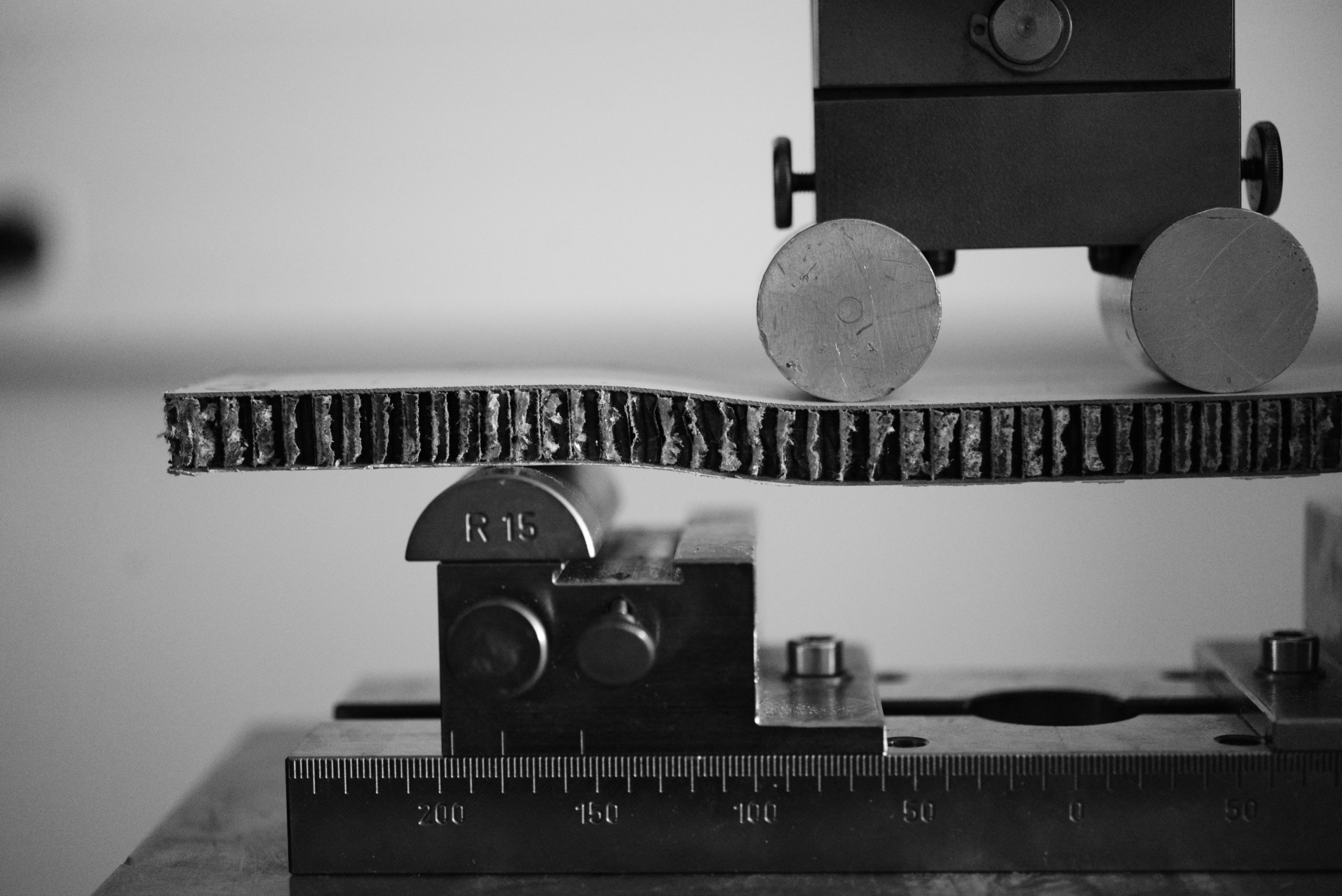

- Bending test – tensile test – compression test

- Peeling: assembly resistance

- Adhesion tests

- Shear – Torsion – Resilience

- Hardness tests

scroll

Composite materials are known for their ability to make structures lighter and are valued in aeronautics, the naval industry, nautical sports, etc. They are used for manufacturing strategic parts and must demonstrate resistance to intense mechanical stress.

We know that securing the mechanical behavior of your innovative materials and assemblies is crucial. We specialize in multiple-property mechanical testing (mechanical, thermal, hygrometry, etc.) and custom create robust economic test fixtures.

Our R&D engineers are intent on applying their scientific rigor in conducting your standardized or complex tests.

Their objective is to approve the strength of your composite parts and prototypes, even in extreme conditions. Our service is complete, from defining test specifications to interpreting results.

Entrusting a local laboratory with your standardized static or custom-developed tests.

Fatigue characterization of your composite materials. Determining your parts’ lifetime behavior and damage tolerance.

Determining composite materials’ strength when exposed to an aggressive environment: immersion, intense heat or humidity, UV exposure, etc.

Designing custom test benches that are adapted to your composite structures, from centimeter-sized samples to parts that are several meters long.

We provide you with reliable accelerated aging data to approve models that can predict your composites’ behavior.

Using appropriate static and dynamic characterizations to determine the durability and reliability of your additively manufactured parts.

Identifying fatigue resistance of welded, glued, bolted/screwed, or multi-material assemblies, in order to reduce residual stresses more effectively.

Capacités teams inspire, harness and couple numerous cutting-edge skills covering a wide range of applications and expertise to meet all of your innovation needs with passion and commitment!

This site uses cookies and gives you control over what you want to enable