A new bio-based thermoplatic from spirulina

Demonstrative-scale production of biomass under solar conditions

Key words

Linked expertise

ONE.FIVE quickly turned to the GEPEA laboratory and the Loire Valley ecosystem as its go-to partners in the microalgae sector. Aiming to develop an innovative bioplastic for the packaging market, the company chose the GEPEA and CAPACITÉS to explore cost-effective production options.

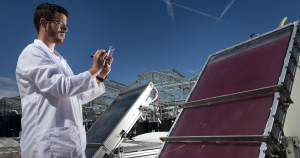

The project was carried out in three stages, resulting in a turnkey production protocol. First, the experts focused on selecting the best strain and culture conditions that met the predefined performance criteria.

A customized cultivation process was then developed. Involving physiological stress, this process doubled the amount of desired polymer. The third and final stage involved plasticizing the biomass using a direct plasticization method, followed by an extrusion step to form a film. The experts then characterized the bioplastic to validate its mechanical strength and thermoplastic properties.

To successfully complete this project, the CAPACITÉS teams used the technical resources of the AlgoSolis R&D facility and benefited from the support of the GEPEA laboratory, joint research unit of Oniris, Nantes Université, IMT Atlantique, and CNRS (French National Centre for Scientific Research).

Our project

These projects may also interest you

Demonstrative-scale production of biomass under solar conditions

Capacités was entrusted for the implementation of the biorefinery process, as well as scaling it up for routine.

ezCOL BV called upon experts in bioprocess engineering from Capacités to scale up the microalgal biomass production and provide the volume necessary for a clinical trial.

This site uses cookies and gives you control over what you want to enable