Producing cholesterol-lowering microalgae at industrial scale

ezCOL BV called upon experts in bioprocess engineering from Capacités to scale up the microalgal biomass production and provide the volume necessary for a clinical trial.

Key words

Linked expertise

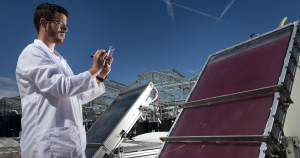

The aim of the European MAGNIFICENT project is to produce microalgae on a large scale and to establish new biorefinery processes in order to reduce production costs and, ultimately, to generate new market opportunities with high added values.

AlgoSource’s contribution to the MAGNIFICENT project consists in optimising the extraction and separation of soluble and insoluble molecules from three strains of microalgae. The challenges they face include the implementation of processes involving several individual operations, as well as improving extraction yields for these high value-added ingredients. The company entrusted Capacités’s bioprocess engineering specialists with adapting the bead milling and tangential flow filtration parameters for two of the microalgal strains, which were developed on a laboratory scale, in order to determine:

the nature and size of the beads, mill residence time necessary to achieve optimal cell destruction, membrane cut-off threshold and filtration surface flow rates. Once the milling and filtration parameters had been approved, our engineers set up a pilot-scale process. Then, using the pilot bead milling at the AlgoSolis platform in Saint-Nazaire, they extrapolated the results obtained at laboratory scale in order to produce pilot batches to be sent on to the MAGNIFICENT project partners for analysis.

To successfully complete this project, the Capacités’experts benefited from support and technical equipment from the GEPEA, joint research unit of the Université de Nantes, Oniris, IMT Atlantique and CNRS (The French National Centre for Scientific Research).

Our projects

These projects may also interest you

ezCOL BV called upon experts in bioprocess engineering from Capacités to scale up the microalgal biomass production and provide the volume necessary for a clinical trial.

An interview with the co-founder and CEO of AlgoSource

GLS is an engineering company specialised in water treatment and, as such, frequently designs wastewater treatment plants. In that context, it must comply with the legal limits of nitrogen and phosphorous content in the treated wastewater discharged from the plant.

SARA recognized Capacités’ experience in strain screening and trusted them with collecting algae strains from their natural environment, isolating them and determining their cultivation parameters.

This site uses cookies and gives you control over what you want to enable