Could you tell us a bit about the challenges of the MAGNIFICENT project? What role did Capacités play?

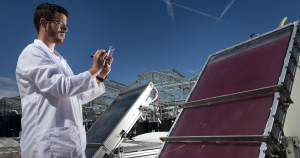

“The MAGNIFICENT project is a European project which aims to develop and scale up marine microalgae refining processes in order to produce ingredients for cosmetics and food. The objective: to reduce microalgae production costs and to generate new market opportunities with high added values.

This project has two facets: on one hand, process development in a laboratory setting using new technologies; on the other hand, unit operation integration on a pre-industrial scale in order to establish technical feasibility and price, as well as to provide data for a life-cycle assessment (i.e., an environmental impact study).

AlgoSource, who was entrusted with scaling up the bead milling and tangential flow filtration parameters, is involved in the second facet, assisted by Capacités. Now it’s up to us to produce the pilot batches to be tested by our clients.”

What made you decide to outsource part of your R&D to Capacités?

“Well, we’ve been using the GEPEA laboratory – Capacités continuum for quite a while now. We are well acquainted with the Capacités team, made up of committed and motivated people supervised by a renowned Professor in microalgae science, as well as with their technical level in bioprocess.

The Capacités – GEPEA cluster is of great benefit to us. Capacités takes full advantage of the technical resources made available to them at the AlgoSolis R&D platform, and there’s one in particular that is quite unique in France although not yet in use: continuous bead milling. We need this equipment in order to validate the biorefinery processes on a pre-industrial scale.

In the exploratory phase, we worked alongside the GEPEA laboratory and Capacités to expand our theoretical analysis of bead mill use. We are still moving towards the pre-industrial scale-up with Capacités.

What we find interesting about Capacités’s offer is that it goes beyond merely delivering a technology: it includes every stage of the extraction process on a pre-industrial scale. Capacités optimises the process, demonstrates its feasibility on an industrial scale, quantifies the results and provides the relevant data to the MAGNIFICENT project partners.

We have very high expectations when it comes to process optimisation with respect to yield, cost and data quality. Capacités has both the experience and the analytical tools to get the job done.”

Following on from your collaboration, what was your impression of Capacités?

“Their biorefinery know-how allowed them to act quickly, to organise their work efficiently and to adapt to any unforeseen events swiftly.”