GEPEA laboratories and CAPACITÉS developed a process whereby the CO2 emitted by a cement plant is used to feed the microalgae, and the waste heat is used to heat the culture tanks. The design and optimisation of this process, which has since been patented, were carried out ar laboratory scale. Studies aimed at optimising the transfer of CO2 to the liquid phase and were carried out in order to maximise the availability of dissolved inorganic carbon during culture. Several strategies geared towards the carbonatation of the growth medium were tested before injecting it into the microalgae tank. The effects of this system on microalgal growth and culture stability were measured in order to select the most favourable environmental conditions (photon flux and duration of sunlight exposure).

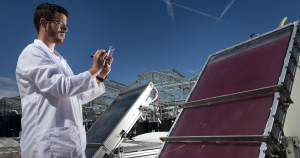

The process automatically adjusts the nutrient requirements of the microalgae and the pH of the tank in response to these changing conditions.

This is achieved via sensors that capture the data from the microalgae culture and send it to the programme. The latter then activates the actuators which add the quantity of medium necessary in order to maintain the sustainability of the culture.

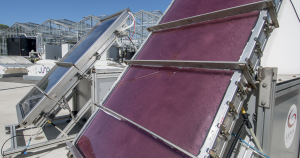

Subsequently, this process was scaled up to a 1 m3 pilot raceway in the greenhouse of the AlgoSolis R&D platform. This transition to a semi-industrial scale made it possible to demonstrate the viability of the system and to obtain a sufficient amount of representative data in order to roll out a demonstrator at semi- industrial scale in a second phase. This second phase is ongoing at Vicat cement plant, next to Lyon (Fr), in collaboration with Total, AlgoSource and the GEPEA laboratory. The pilot plant should be inaugurated in September 2021.

To successfully complete this project, the Capacités’experts benefited from support and technical equipment from the GEPEA, joint research unit of the Université de Nantes, Oniris, IMT Atlantique and CNRS (The French National Centre for Scientific Research).