Biorefining microalgae: successfully scaling up

An interview with the co-founder and CEO of AlgoSource

Key words

Microalgae are able to assimilate the nitrogen and phosphorous pollution in wastewater. It is with this in mind that GLS, an engineering company specialising in water treatment, wished to commit to an innovation strategy making use of microalgae. To achieve this goal, they chose to rely on the expertise of the microalgal cultivation and valorisation specialists at the GEPEA laboratory, as well as on the top-notch bioprocess engineers at Capacités.

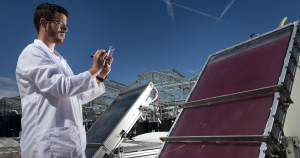

After having completed a preliminary characterisation of the reclaimed wastewater, Capacités’s experts confirmed the technical requirements for cultivating algae in a laboratory environment. They were then able to transfer this cultivation process to raceway ponds (with water circulation) at the AlgoSolis R&D platform.

The raceways, which are installed outdoor and received real wastewater from a local plant, ran continuously for 6 months in order to be able to account for the effects of seasonal changes at pilot scale.

The experiment was thus able to demonstrate an effective reduction of nitrogen and phosphorous via this open cultivation system. It also revealed the relevant parameters and their impacts on the process. Upon completion of their research, Capacités’s specialists were able to deliver a viable techno-economic model, taking the respective constraints of wastewater treatment plants, algal cultures and biomass valorisation into consideration.

To successfully complete this project, the Capacités’experts benefited from support and technical equipment from the GEPEA, joint research unit of the Université de Nantes, Oniris, IMT Atlantique and CNRS (The French National Centre for Scientific Research).

OUR PROJECTS

These projects may also interest you

An interview with the co-founder and CEO of AlgoSource

As part of an industrial ecology initiative aimed at mitigating waste heat and industrial effluents rich in CO2 that are produced by cement plants, ADEME (French Agency for Environment and Energy Management) funded the project “CIMENTALGUE”.

ezCOL BV called upon experts in bioprocess engineering from Capacités to scale up the microalgal biomass production and provide the volume necessary for a clinical trial.

Capacités was entrusted for the implementation of the biorefinery process, as well as scaling it up for routine.

This site uses cookies and gives you control over what you want to enable