Using cyclodextrins encapsulation to increase the bioavailability of a hydrophobic active ingredient

Capsulæ is a leading company in the field of microencapsulation. It develops solutions for industrial customers to optimize active and inactive ingredients’ performance and facilitate their use. The company had a project that required finding an effective alternative solution to meet its client’s biodegradability requirements. It turned to the experts from CAPACITÉS to develop a new formula involving its method of encapsulation by cyclodextrins. The preliminary results are promising.

Increasing the bioavailability of a hydrophobic active ingredient

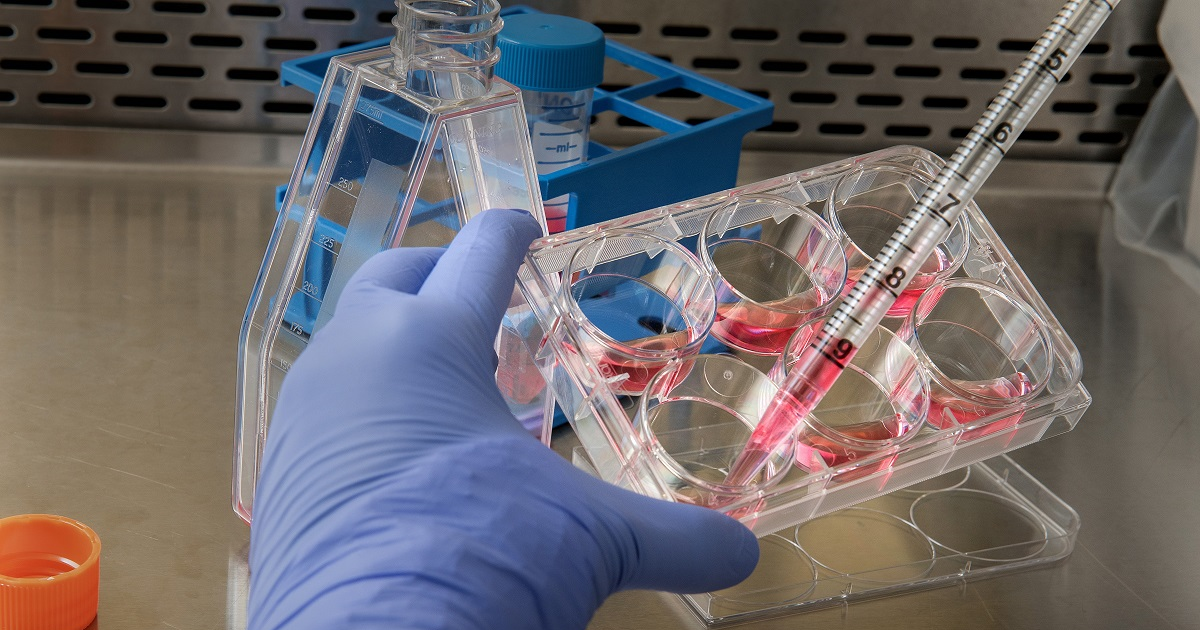

In the fields of food and feed, microencapsulation can improve an active ingredient’s stability. “Nevertheless, using conventional encapsulation materials does not always let us obtain all the beneficial effects from some active ingredients. This is due to weak bioavailability and is often linked to hydrophobicity,” explains Gisèle Ongmayeb, PhD, the R&I manager at Capsulæ.

Capsulæ wanted to explore other materials with structures that can protect hydrophobic active ingredients and simultaneously facilitate their bioavailability. Cyclodextrins were identified among these materials. They originate naturally and meet current regulatory demands concerning material biodegradability.

In this context, the company asked CAPACITÉS’ experts to encapsulate vitamin E as a model molecule. The intermediary results are very encouraging; the cyclodextrins selected allowed vitamin E to be encapsulated and improved its solubility in an aqueous phase. The results delivered in August 2021 confirm this trend, and a second phase of the project will begin with the aim of optimizing the process to reduce costs. Capsulæ’s goal is to offer its clients an innovative encapsulation technique at a competitive price.

An efficient collaboration in Research & Innovation for industry

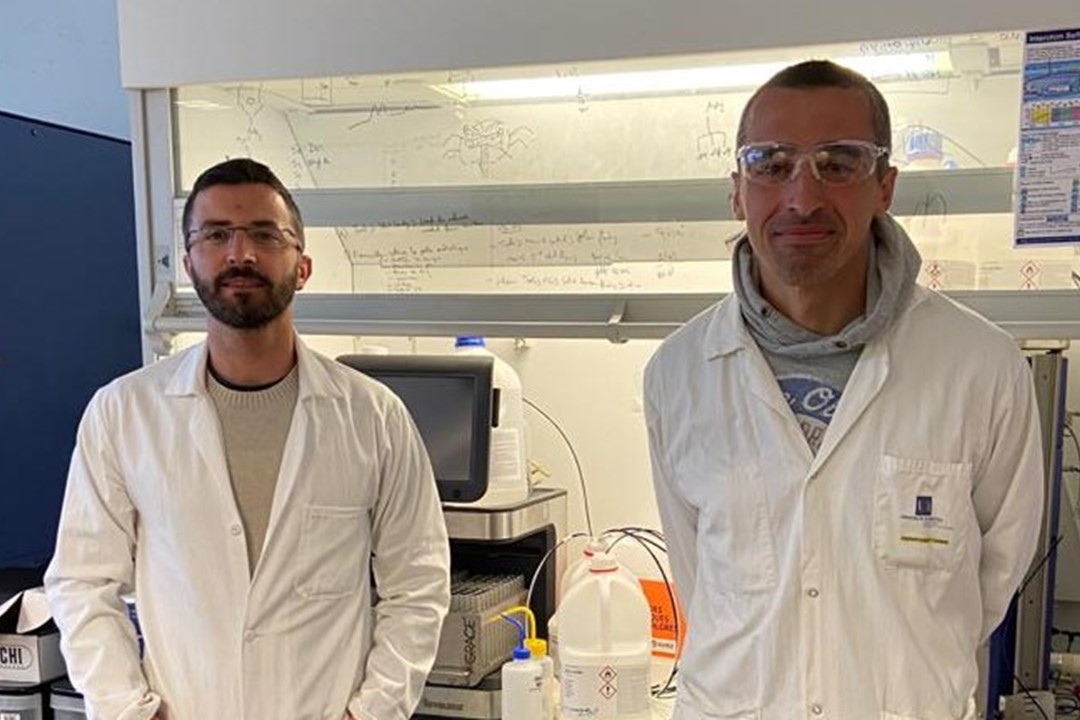

“Private companies must join forces with researchers in academic laboratories, such as the experts at CAPACITÉS, to overcome certain scientific obstacles and use the latest methods of characterization. So, you must collaborate to innovate,” recommends Gisèle Ongmayeb.

In the context of this collaboration, “CAPACITÉS has knowledge and a high level of scientific expertise in a particular groundbreaking skill. Capsulæ has extensive experience and a unique global vision of the encapsulation market. For CAPACITÉS, this is the opportunity to make full use of its expertise with cyclodextrins for new industrial applications,” adds Gisèle Ongmayeb.

Do you need help solving bioavailability issues for an active compound? CAPACITÉS is your partner for finding ingenious solutions. Contact us.