Producing cholesterol-lowering microalgae at industrial scale

ezCOL BV called upon experts in bioprocess engineering from Capacités to scale up the microalgal biomass production and provide the volume necessary for a clinical trial.

Key words

Linked expertises

A key player in the field of macroalgae valorisation, BiotechMarine called upon the specialists at Capacités to optimise the parameters of its cultivation process. This manufacturer needed, in particular, to find out whether the concentration of dissolved inorganic carbon (DIC) in the culture medium might have an influence on the development of a particular strain of red alga.

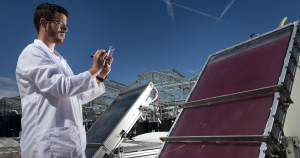

In order to fulfil this request, Capacités’s bioprocess engineers began cultivating this strain in an Airlift photobioreactor. This closed and controlled environment facilitates the precise management and reproduction of the physico-chemical parameters of the cultivation process: sterility, temperature, luminosity and pH, as well as the concentration of dissolved inorganic carbon (DIC).

Several sets of parameters were tested in order to compare cultivation conditions and the quantity of biomass produced. Furthermore, the correlation between the concentration of DIC and the quantity of biomass was very closely monitored during these tests.

Based on the results obtained, the experts were unable to demonstrate a connection between the concentration of DIC and the growth of the red macroalgal strain. However, during the course of this same study, they were able to improve the strain’s productivity by modifying other parameters of the process.

To successfully complete this project, the Capacités’ experts benefited from support and technical equipment from the GEPEA, joint research unit of Université de Nantes, Oniris, IMT Atlantique and CNRS (The French National Centre for Scientific Research).

Our projects

These projects may also interest you

ezCOL BV called upon experts in bioprocess engineering from Capacités to scale up the microalgal biomass production and provide the volume necessary for a clinical trial.

Capacités was entrusted for the implementation of the biorefinery process, as well as scaling it up for routine.

An interview with the co-founder and CEO of AlgoSource

GLS is an engineering company specialised in water treatment and, as such, frequently designs wastewater treatment plants. In that context, it must comply with the legal limits of nitrogen and phosphorous content in the treated wastewater discharged from the plant.

This site uses cookies and gives you control over what you want to enable